Bioreactor Types Pdf

About Author:

Kambham Venkateswarlu

Graduate Student

Sri Lakshmi Narasimha College of Pharmacy,

Palluru, Chittoor District, Andhra Pradesh-517132, India.

k.v.reddy9441701016@gmail.com

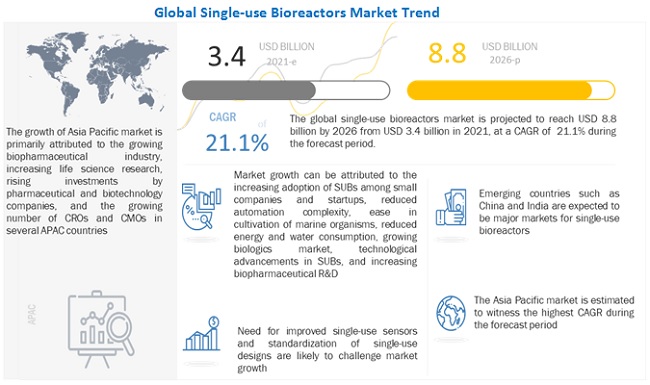

Bioreactor design and scale-up 2.4.1. Bioreactors for cell suspension 2.4.2. Fixed bed and fluidized bed reactors 2.4.3. Hollow fiber and membrane reactors 2.4.4. Single-use bioreactors 3. Insect cell culture 4. Plant cell culture 5. Tissue engineering and stem cell culture 5.1 Bioreactor concepts for tissue engineering.

ABSTRACT:

Many different types of laboratory fermentors and bioreactors are used worldwide. The selection of a good quality bioreactor is not easy. Some advantageous parameters found in one product are cancelled out by other draw backs in the same system. Good high quality bioreactors are very expensive. Even then ease of use is not assured. The question arises, whether it is possible to construct a bioreactor, which would satisfy most requirements. The most important are high quality and easy to use, perfect sterility, precise measurement, control and recording of all important culture parameters and lasts but not lasts, and the bioreactor shouldn’t expensive!

Based on long personal practical experience in the field, we have tried to analyse the requirements and select technical solutions, which would lead to the satisfaction of the criteria presented above. In the following sections several important parameters will be briefly described and new solutions suggested.

Reference Id: PHARMATUTOR-ART-1601

CLASSIFICATION OF BIOREACTORS:

There are numerous types of bioreactors - batch, sequence, continuously stirred tanks, anaerobic contact processes, anaerobic filters, etc.

1. They can be conveniently classified into three major types based on the presence or absence of oxygen and requirement of stirring.

• Non stirred non aerated bioreactors are used for production of traditional products such as wine, beer, cheese etc.

• Non stirred aerated reactors are used much rarely.

• Stirred and aerated reactors are most often used for production of metabolites which require growth of microbes which require oxygen. Most of the newer methods are based on this type of bioreactors.

2. Based on mode of operation, the bioreactors can be classified into three types.

• Batch reactors

• Fed batch

• Continuous e.g.: chemostat

3. Based on the method of growing of microbes, bioreactors can be either Suspended or Immobilized.

The Petri dish is the simplest immobilized bioreactor. The large scale immobilized bioreactors are used for commercial manufacturing of metabolites. They include

- Moving bed

- Fibrous bed

- Packed bed

- Membrane

Youtube cinema paradiso music. 4. On the basis of the microbial agent used, the bioreactors can be classified into

• Those based on living cells

• Which employ enzymes

5. Based on the process requirements, bioreactors can be classified into

a. Aerobic

b. Anaerobic

c. Solid state

d. Immobilized

Retrieved 12 December 2017. Eminem sing for the moment mp3 song free download. Entertainment Weekly. September 17, 2009.

I. Aerobic fermentation

These reactors should have adequate provisions for supply of sterile air and also need a mechanism of stirring up and mixing the medium and cells.

a. Stirred tank or

b. Air lifts type

Generally, they are either closed type or batch reactors. Some special cases use continuous flow reactors also.

1. Stirred tank bioreactor

This is the conventional mixing reactor which is made of either glass or stainless steel. The stirrer can be either at the top or bottom of the reactor. The dimensions of the reactor depend on the amount of heat to be removed from the vessel. Baffles in the centre of the tank prevent formation of vortex and effective mixing of the ingredients.

The continuous stirred-tank reactor(CSTR), also known as vat- or back mix reactor, is a common ideal reactor type in chemical engineering. A CSTR often refers to a model used to estimate the key unit operation variables when using a continuous[†]agitated-tank reactor to reach a specified output. (See Chemical reactors.) The mathematical model works for all fluids: liquids, gases, and slurries.

The behavior of a CSTR is often approximated or modeled by that of a Continuous Ideally Stirred-Tank Reactor (CISTR). All calculations performed with CISTRs assume perfect mixing. In a perfectly mixed reactor, the output composition is identical to composition of the material inside the reactor, which is a function of residence time and rate of reaction. If the residence time is 5-10 times the mixing time, this approximation is valid for engineering purposes. The CISTR model is often used to simplify engineering calculations and can be used to describe research reactors. In practice it can only be approached, in particular in industrial size reactors.

Assume:

· perfect or ideal mixing, as stated above

Integral mass balance on number of moles Ni of species i in a reactor of volume V.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

FIND OUT MORE ARTICLES AT OUR DATABASE